Gas fittings are small yet essential components that allow gas to flow safely from supply lines to appliances.

You’ll find them in homes, caravans, and industrial sites where they help fuel stoves, heaters, and machinery. But the different types of gas fittings and threads can be confusing.

If you’re setting up a BBQ gas fitter, fixing a caravan line, or managing a commercial system, it’s critical to know what fitting to use and why.

This guide covers the most common gas fitting types, how threads work, installation tips, and safety advice.

Gas fittings connect pipes, hoses, and appliances to create a sealed link for pressurised gas. Depending on the use, they must endure heat, movement, or outdoor exposure.

Each setup requires a different fitting. If you get this wrong, you will risk leaks or total damage. If you get this right, you’ll get a safe, long-lasting connection

The following are the most commonly used gas fittings in Australia. Each type serves a different purpose and uses a unique connection method.

Flare fittings involve a conical pipe end that’s flared outward, fitting snugly into a matching seat. They’re tightened with a nut to seal without tape. These are popular in LPG systems and caravans where vibration resistance matters.

Compression fittings use a brass olive (ring) compressed by a nut to seal the pipe. They’re ideal for copper piping, which is common in indoor installations. No special tools are required, but precision matters to avoid leaks.

Bayonet fittings have a twist-lock mechanism.

A male fitting is pushed into a female socket and rotated to lock. They can connect to gas heaters, BBQs, and caravan appliances due to their quick-connect convenience and self-sealing valve.

Quick-connect fittings (also called quick-fit gas connectors) use a spring-loaded mechanism for fast, tool-free hookups. They’re most commonly used as BBQ gas fitters, often found in outdoor setups for connecting patio heaters.

These fittings allow pipes to be pushed in directly and locked with internal seals. They’re commonly used in modern caravan systems or kits, but only when rated for gas (not just water). Simple to install but limited to specific setups.

Gas threads on gas fittings are designed to screw components together tightly enough to form a sealed path for gas to travel. When working with different types of gas fittings, getting the threading right is just as important as choosing the correct size or material.

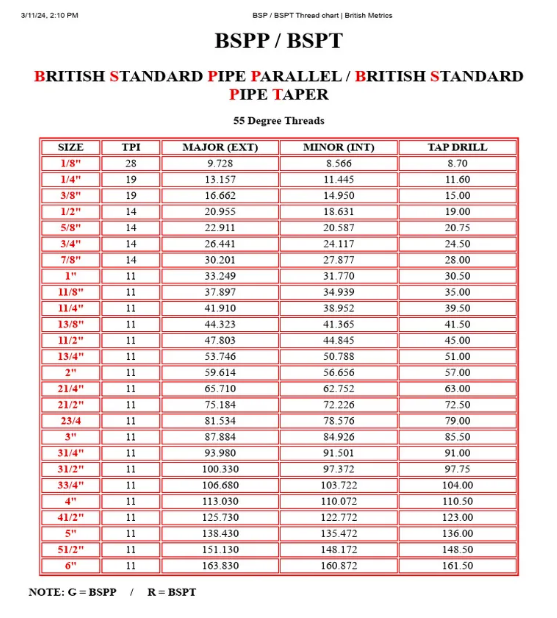

In Australia, BSP (British Standard Pipe) threads are the norm. BSPT (tapered) threads seal by tightening, while BSPP (parallel) threads need washers or O-rings to form a seal.

NPT (National Pipe Thread), used in North America, has a different angle and spacing and isn’t compatible with BSP threads. Mixing them can lead to leaks or even stripped threads.

Male threads are external, and they screw into internal female threads.

Many gas fittings, especially for LPG bottles or caravan setups, use left-hand threads, which tighten counter-clockwise. These are usually marked with notches or indicators to avoid confusion.

Only tapered threads need sealants. Use yellow PTFE tape or an approved gas-rated paste. Don’t use sealants on flare or compression fittings, since they rely on direct metal contact to form the seal. Extra material can actually interfere.

Also Read: How Long Does a Gas Stove Last?

In Australia, most domestic and light commercial gas fittings are made from brass or stainless steel. Each has its own advantages, depending on where and how the fitting is being used.

Steel Brass is widely used for good reason. It resists corrosion, is easy to work with, and forms tight seals. You’ll find it in BBQ hoses, caravan regulators, and indoor cooktop fittings. Brass works well for both natural gas and LPG systems.

Stainless steel, on the other hand, is much tougher. It can handle higher pressures and is ideal for harsh environments like coastal areas or industrial kitchens. While more expensive and harder to thread, stainless steel fittings last longer and provide added strength.

Common sizes in Australia include 1/4″, 3/8″, 1/2″, and 3/4″ BSP. These labels refer to the internal pipe diameter, not the outer measurement.

A 3/8″ BSP thread, for example, is roughly 16 mm across. This often causes confusion, so professionals usually rely on sizing charts or thread gauges.

Always check your fittings for compatibility. Confirm the thread standard (BSP vs NPT), match male and female threads, and never force a connection.

If it doesn’t go in smoothly by hand, it’s likely the wrong type or size. Forcing a thread can cause damage that leads to dangerous leaks.

Selecting the correct fitting goes beyond picking the right size or thread. It depends on where the fitting will be used, what type of gas is involved, and whether the application requires mobility, high pressure, or weather resistance.

Indoor setups are usually fixed installations, like a pipe behind a stove or heater. These often use compression or flare fittings and are hidden from view.

Outdoor setups need fittings that resist weather and movement. For these, brass or stainless steel is best. They’re useful for quick-fit gas connectors, usually installed in BBQ systems and heaters.

LPG systems run at higher pressure and are more portable. You’ll often see flare fittings, POL connectors, or threaded joints rated for high PSI.

Natural gas systems are hard-piped from the mains and operate at lower pressure. These setups typically use bayonet or compression fittings that stay in place.

Caravans combine portable and fixed components. Bayonet fittings are ideal for BBQs or heaters that need to be disconnected. POL fittings connect LPG bottles to regulators.

Inside the caravan, flare and compression fittings secure appliances. Since caravans move, fittings must resist vibration and hold firm.

Most fittings include visual clues. These may include stamped sizes, BSP labels, or marks indicating left-hand threads. Some have grooves or bands that signal thread direction. These help avoid mismatches and speed up the installation.

Following a few critical safety practices can drastically reduce risks and help ensure that your connections remain secure and compliant.

If you’re doing DIY, try to connect to a gas fitting by using a BBQ hose, a gas bottle, or plugging into a bayonet socket. But if you’re installing new fittings, running gas lines, or working inside a wall, you’ll need a licensed gas fitter. This is required by law in Australia and ensures the work is safe and certified.

Every fitting must be tested after installation. The soapy water method is simple. Mix soap with water, brush it over the joint, and watch for bubbles. If bubbles form, there’s a leak. Shut off the gas, recheck the fitting, and fix it. Always retest until no bubbles appear.

Cross-threading happens when you screw a fitting in at the wrong angle. It damages the thread and ruins the seal. To prevent it, start every thread by hand. If it doesn’t turn smoothly, stop and realign. Never force a connection.

All gas work must follow AS/NZS 5601. Licensed gas fitters provide compliance certificates, which prove that the job meets the code. This is important for home insurance, future resale, and safety. Uncertified gas work is risky and illegal.

For larger tasks—or anything involving permanent changes—call a licensed professional like Melbourne Gas Plumber.

Even with the correct gas fittings and careful installation, things can go wrong over time. Knowing how to identify and fix common problems will help you maintain a safe and efficient system.

Leaks happen from loose connections, bad seals, or worn-out parts. You might hear a hiss or smell a rotten egg odour (from the gas additive). Use the soap test to check. Shut off the gas and fix or replace the fitting.

If a fitting doesn’t tighten properly or seems wobbly even when secured, it may be the wrong size or thread type.

This is common when mixing BSP with NPT fittings or using a fitting that has been previously damaged. Never force a fitting to tighten and always verify that you’re using compatible types.

Trying to pair BSP with NPT threads is a common mistake. While they might seem close in size, they differ in pitch and angle, preventing a proper seal. Mixing them often leads to leaks and cross-threading.

Always check for markings on the fitting or consult the manufacturer’s specs. If in doubt, replace with a clearly labelled BSP fitting to stay compliant in Australia.

Threads wear down over time or get stripped from overtightening. If you see metal shavings or rough threads, replace the part. No amount of sealant can fix a ruined thread.

When in doubt, call a licensed professional like Melbourne Gas Plumber to inspect and repair the issue.

Gas fittings may be small parts, but their role is massive. They’re responsible for sealing high-pressure fuel lines, supporting portable and fixed appliances, and ensuring safety across a wide range of environments.

If there’s any doubt in your mind about what fitting to use, how to connect it, or whether your system is compliant, always consult a licensed professional.

Need help? Melbourne Gas Plumber can inspect, install, and maintain your gas fittings to keep your home, caravan, or business running safely and smoothly.

Still got questions? Let’s clear things up with these commonly asked questions about gas fittings.

No. Australia uses BSP threads. NPT threads have different angles and spacing and won’t seal properly. Mixing them can result in leaks or stripped threads.

Use callipers to measure the thread diameter and compare it to a BSP sizing chart. Alternatively, bring the old fitting to a hardware store or gas specialist for a match. Guessing often leads to mismatched connections.

Flare fittings use a flared metal pipe that seals against a cone seat, no tape needed. Compression fittings use a brass ring squeezed onto the pipe by a nut. Both are effective, but flare fittings offer better vibration resistance.

Not entirely, but caravans often use flare and bayonet fittings due to their portability and self-sealing features. You’ll also commonly see POL connections for LPG bottles. These fittings are tailored for compact, mobile setups where safety during movement matters most.

Fill the form below and we’ll get back ASAP!

MGP! Thank you for help, honest pricing and high quality work. Thank you to Joe for pricing and the boys involved for replacing my hot water tank and fixing my gas leak for a reasonable price. 5 star response, 5 star service and 5 star price.

Joe was great. Very professional and quick. Gas hot water heater needed replacing, he was honest and upfront about what our options were. System was sourced and replaced within a couple of hours.

Fantastic service very responsive Joe is highly recommended and works very clean and neat..... good job well done....very happy... will use again and again

At Melbourne Gas Plumber, we're here to handle all your gas plumbing needs throughout Melbourne. With over 40 years of experience, we bring extensive local knowledge and expertise to every job.

QUICK LINKS

OPENING HOURS

Open 24/7