If your Melbourne home was built before 1980, there’s a fair chance your gas pipes are galvanised steel. Those silver pipes used to define Australian gas installs. But are they safe today?

This guide explains what galvanised pipe is and whether you can use it for new gas installation that meets safety standards. Read on.

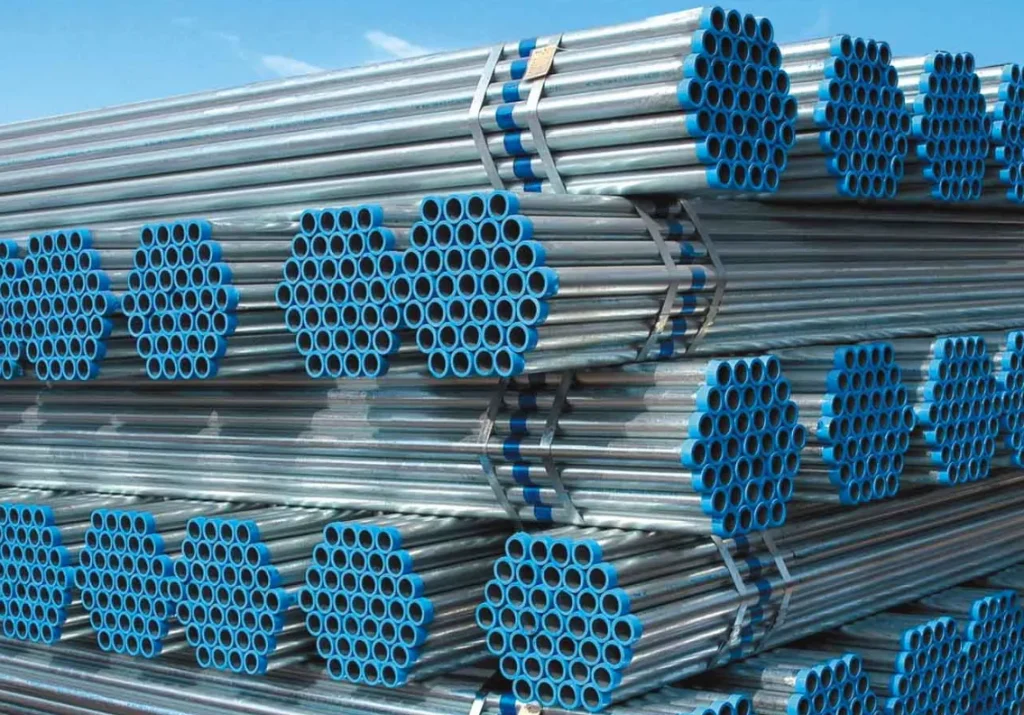

Image by minjiesteel.com

A galvanised pipe is a steel or iron pipe that gets a zinc coating through galvanising. This chemical process helps stop corrosion, rust, and mineral buildup that hits untreated steel.

The most common method is hot-dip galvanising, which means dipping the pipe in a bath of molten zinc at about 450°C. That creates a permanent bond and gives the pipe its silver-grey appearance.

You can find galvanised pipes at home in three ways.

One, they’re magnetic. Two, they have threaded ends where pipes screw together with big nuts. Three, they’re stiff and thick-walled (unlike modern copper pipes, which are thinner and brownish).

So, if you find pipes with these three features in your home, they are likely galvanised steel gas pipes, typically ranging from 15 mm for appliance connections to 32 mm for main lines.

In Australia, galvanised gas pipes follow AS 1074. The standard sets the carbon steel grade and the zinc layer, which is usually about 42–63 microns thick.

While galvanised pipes resist external corrosion well, their suitability for gas systems is questionable.

Image by apex-steel.com

The short answer is yes. Galvanised steel is still a common and legal material for some gas pipe work in Australia.

But newer standards and industry practice are leaning toward other options for new installs. You’ll see some gas fitters suggest other materials for new gas installations, including:

But the main issue isn’t compliance, it’s safety.

If the zinc coating wears away over more than 50 years, it flakes off and can clog regulators, valves, and burner holes, causing flow problems and malfunctions that might need gas leak detection service to check that.

Note that in many regions, building codes allow galvanised steel for gas distribution but with specific requirements:

Adding to that, AS/NZS 5601.1:2022, the current Australian and New Zealand gas installation standard, allows galvanised steel pipe for above-ground gas installations but prohibits it underground.

And if you’re unsure, double-check your local gas standards and amendments for your area, especially in Melbourne and Sydney.

Image by mayersteelpipe.com

When it comes to gas piping, black steel pipe has become the industry standard over galvanised steel.

Black steel, or black iron, is carbon steel pipe without zinc protection. It is uncoated mild steel that forms a natural iron oxide (Fe₃O₄) layer during manufacture, which gives it its dark grey or matte black appearance.

Black steel remains the preferred choice for gas installation due to its affordability and durability in dry areas. Plus, they’re approved under AS/NZS 5601.1:2022 and work with natural gas, LPG, and biogas.

Black steel pipes can handle high pressure above or underground, but they are easily harmed by moisture. So, it’s often coated with plastic or other protective materials when burying the gas line underground is needed.

Galvanised pipes apply zinc coating. That’s what makes it cost more to produce due to the extra steps. They resist external rust in humidity, but internal risks to gas appliances often outweigh that benefit.

On the other hand, galvanised pipes get a zinc coating. That makes them resist external rust in humidity. Unfortunately, internal risks to gas appliances often outweigh that benefit.

When a project requires strong external corrosion resistance for a gas line, engineers typically recommend specialised coatings on black steel or using stainless steel instead of standard galvanised pipe.

| Characteristic | Black Steel (Black Iron) | Galvanised Steel |

| Material Composition | Carbon steel with black oxide surface | Carbon steel with zinc coating (typically tens of micrometres thick) |

| Durability | Around 20–50 years in typical indoor gas service, depending on environment and protection | Commonly around more than 40–50 years when properly protected and maintained |

| Corrosion Resistance | Moderate (uncoated steel needs a dry or protected environment) | High external protection from zinc coating in many environments |

| Cost (Material) | Lower (no galvanising step) | Higher (additional galvanising process) |

| Safe for Gas? | Yes (permitted under AS/NZS 5601.1:2022 when installed to the standard) | Yes (permitted under AS/NZS 5601.1:2022 and modern gas quality standards) |

| Flaking Risk | No zinc flaking mechanism | Negligible risk with modern refined (sweet) natural gas; historically linked to high-sulfur gas. |

| Pressure Handling | Excellent (widely used for gas system pressures when designed correctly) | Similar steel pressure capacity; widely used and permitted in various jurisdictions. |

| Typical Lifespan in Gas | Commonly around a few decades (about 20–50 years, depending on conditions) | Service life can extend for decades when corrosion is controlled. |

| Compliance | Compliant when designed and installed per AS/NZS 5601.1:2022 and Victorian regulations | Compliant when designed and installed per AS/NZS 5601.1:2022 and Victorian regulations |

What about using both and mixing them? No. There’s a big risk with gas pipes when you mix different materials, especially underground.

When those two metals touch in damp soil or water, a galvanic reaction can occur. This electrochemical process speeds up rust and thins the pipe wall, which can lead to dangerous gas leaks.

Keep in mind that simply capping the gas line may not resolve this issue.

Here are questions about using galvanised pipe for gas:

Natural gas itself doesn’t aggressively corrode galvanised steel, but it can react with the zinc coating or carry moisture that makes zinc flake off over time.

Those flakes can travel through the system and clog regulators and burners. This reaction accelerates over time, particularly in pipes older than 30 years.

Several pipe materials aren’t suitable for gas installations under AS/NZS 5601.1:2022. Copper pipes are approved for LPG but can suffer surface sulfidation if the gas has high sulphur impurities.

PVC and other standard plastics aren’t allowed for gas, except for specifically approved PE or multilayer pipes. Galvanised pipe is being discouraged due to zinc flaking risks, though some older systems remain in service.

Galvanised gas pipes typically last 20 to 50 years, depending on the gas type, environmental conditions, and installation quality.

In Melbourne’s humid climate, they corrode faster. Most galvanised pipes show significant wear after 40 years, with many failing before reaching 50 years.

Grasping the risks of galvanized gas pipes is vital for any home, especially if it’s built before the 1980s. They worked back then, but today’s safety standards prefer black steel for reliability and no zinc flaking risk.

If your home has galvanised gas pipes, have them checked by a licensed professional. Surface issues may hide interior corrosion that risks your family.

We at Melbourne Gas Plumber can help you with replacing old galvanised pipes with approved black steel or modern materials, bringing your system up to AS/NZS 5601.1:2022 standards.

Fill the form below and we’ll get back ASAP!

MGP! Thank you for help, honest pricing and high quality work. Thank you to Joe for pricing and the boys involved for replacing my hot water tank and fixing my gas leak for a reasonable price. 5 star response, 5 star service and 5 star price.

Joe was great. Very professional and quick. Gas hot water heater needed replacing, he was honest and upfront about what our options were. System was sourced and replaced within a couple of hours.

Fantastic service very responsive Joe is highly recommended and works very clean and neat..... good job well done....very happy... will use again and again

At Melbourne Gas Plumber, we're here to handle all your gas plumbing needs throughout Melbourne. With over 40 years of experience, we bring extensive local knowledge and expertise to every job.

QUICK LINKS

OPENING HOURS

Open 24/7